| Sign In | Join Free | My xxjcy.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My xxjcy.com |

|

Brand Name : YUHONG

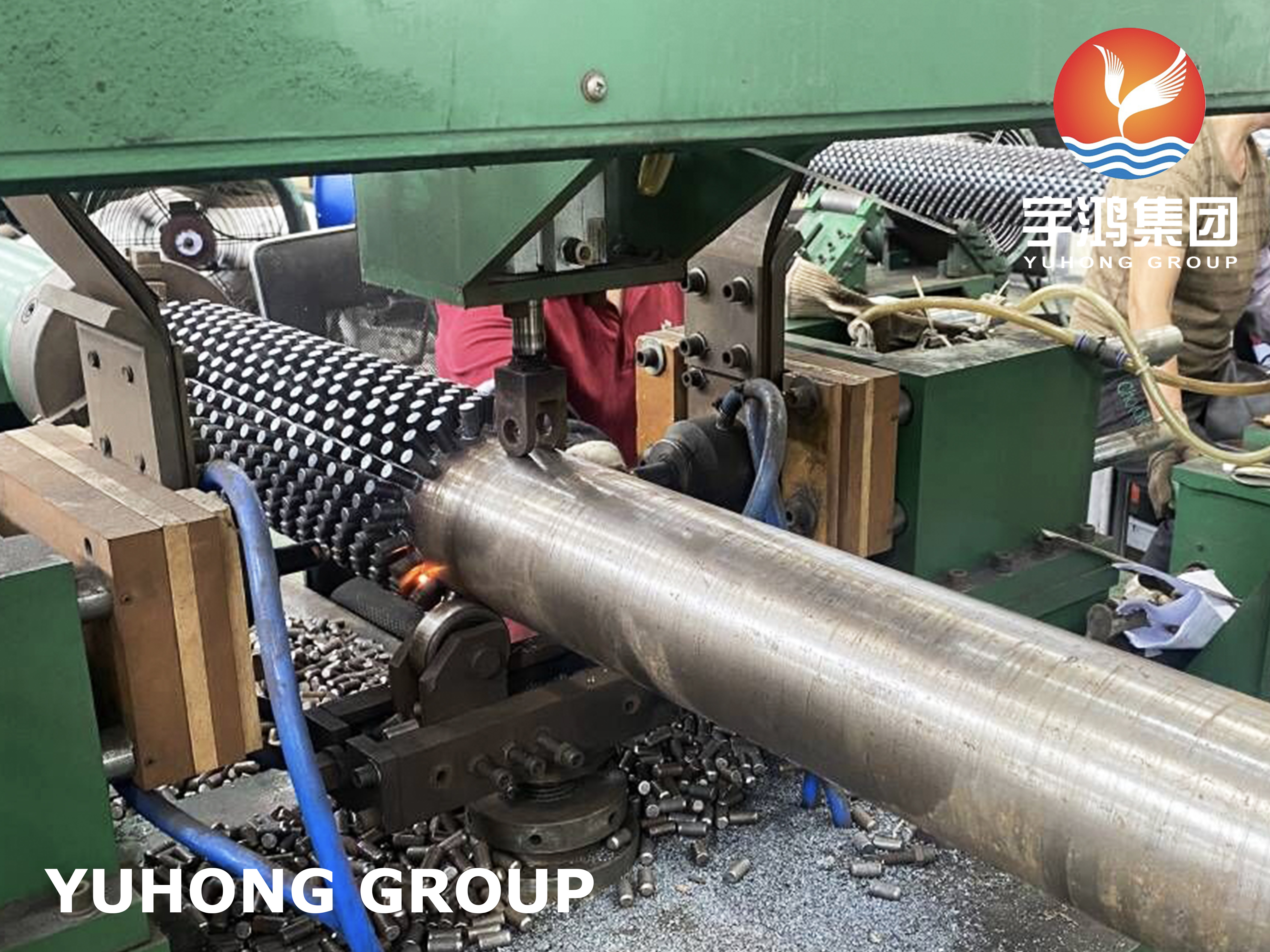

Model Number : SS304 Stainless Steel Stud Fin Tube

Certification : ISO9001, PED etc.

Place of Origin : CHINA

MOQ : 1PC

Price : Negotiable

Payment Terms : T/T, L/C AT SIGHT

Supply Ability : 10000 pcs per month

Delivery Time : Depends on quantity

Packaging Details : Iron frame wooden box

Product Name : SS304 Stud Fin Tube

Base Pipe Material : A312 TP304 / Other Material

Stud Material : Carbon Steel / Alloy Steel

Weld Type : High Frequency Welded(HFW)

Overview

Stainless Steel 304 Stud Fin Tube is a specialized heat transfer component used primarily in heat exchangers, air-cooled heat exchangers, and other industrial applications where enhanced thermal conductivity is essential. It combines the properties of stainless steel 304 with stud finning technology to maximize heat transfer efficiency. The structure typically consists of a smooth tube with external fins or studs that increase the surface area available for heat exchange.

Key Features of Stainless Steel 304 Stud Fin Tube:

Material: Stainless Steel 304

Corrosion Resistance: SS304 is highly resistant to corrosion, making it ideal for use in harsh environments, such as chemical plants, food processing, marine environments, and oil and gas industries.

Durability: SS304 is known for its excellent mechanical properties, including high tensile strength, which makes it durable under high-pressure conditions.

Temperature Resistance: SS304 can withstand high temperatures (up to 870°C in intermittent service), making it suitable for applications involving thermal transfer in demanding conditions.

Formability: Stainless steel 304 is easy to fabricate and can be welded, making it suitable for manufacturing the stud fin tube with the desired specifications.

Stud Fin Technology

Increased Surface Area: The "stud" refers to small protrusions or projections attached to the fins of the tube. These studs help increase the surface area, improving the efficiency of heat transfer between the tube and the surrounding fluid (air, water, or other substances).

Enhanced Turbulence: The studded design helps to induce turbulence in the fluid flowing around the tube, which disrupts laminar flow and increases the rate of heat transfer. This is particularly important for applications where enhanced heat dissipation is critical.

Efficient Heat Exchange: The combination of fins and studs ensures that more heat can be transferred with a relatively smaller surface area, which is beneficial for compact designs.

Applications of SS304 Stud Fin Tube

Heat Exchangers: Widely used in both liquid-to-air and gas-to-air heat exchangers, where enhanced heat transfer is necessary.

Air-Cooled Heat Exchangers: Stud fin tubes are commonly used in air-cooled heat exchangers for industries such as power generation, petrochemicals, and HVAC systems.

Refrigeration and HVAC: They are frequently used in evaporators, condensers, and cooling coils in refrigeration and air conditioning systems.

Boilers and Steam Systems: In industries like power plants and chemical processing, these tubes are used in economizers, superheaters, and steam condensers to improve heat recovery efficiency.

Marine Cooling Systems: Due to their corrosion resistance and efficiency in heat transfer, SS304 stud fin tubes are used in marine applications for cooling systems.

Advantages of Stainless Steel 304 Stud Fin Tubes:

Corrosion Resistance: Stainless steel 304’s resistance to corrosion ensures long-lasting performance, especially in aggressive environments like chemical processing, marine, and offshore applications.

Compact and Efficient: Stud fin tubes provide high heat transfer efficiency while keeping the system compact. The studs and fins optimize the use of space, making them suitable for installations with space constraints.

Durability: Stainless steel 304 is highly durable and able to withstand mechanical stresses and thermal cycling, ensuring a longer lifespan of the heat exchanger or other systems where they are used.

Improved Heat Transfer: The combination of studs and fins provides more surface area and creates turbulence in the fluid, which significantly improves the rate of heat transfer compared to bare tubes.

Design Flexibility:

Customization: The design and dimensions of SS304 stud fin tubes can be tailored to meet the specific requirements of various applications, including custom lengths, fin patterns, and stud configurations.

Variety of Tube Sizes: These tubes come in a range of sizes, diameters, and thicknesses, ensuring compatibility with various system designs.

Applications in Various Industries

Oil & Gas: In offshore and onshore processing plants, for heat exchange in pipelines, coolers, and heat recovery systems.

Chemical and Petrochemical Plants: For cooling, heating, or condensing systems where enhanced heat transfer is necessary to maintain process temperatures.

Food and Beverage: In food processing and refrigeration applications to efficiently manage thermal energy.

Power Generation: In cooling towers, steam condensers, and economizers to optimize the use of waste heat and improve energy efficiency.

Marine: For cooling systems, particularly in saltwater environments where corrosion resistance is crucial.

Conclusion

Stainless Steel 304 Stud Fin Tubes are highly effective components for improving heat transfer in various applications, especially in demanding industries. Their combination of stainless steel 304’s corrosion resistance and mechanical strength, along with the enhanced thermal efficiency from the stud fin design, makes them a valuable choice for heat exchangers, cooling systems, and other thermal management applications. The ability to withstand high temperatures and harsh environments makes them an excellent solution for applications in power plants, oil and gas, marine, and other industrial sectors.

|

|

SS304 Stainless Steel Stud Fin Tube High Frequency Welded HFW For Steam Generator Images |